Laser cutting has become an increasingly popular method for cutting materials such as metal, plastic, wood, and glass. A wide variety of industries, including automotive and medical device industries use laser cutting because it offers a high degree of accuracy and precision. Each of these industries has different requirements and uses laser cutting in different ways. The automotive industry, for example, utilizes laser cutting to create car parts and components. The medical device industry creates medical devices and implants with laser cutting.

The automotive industry has embraced the advantages offered by laser cutting to produce a range of components. Tolerances in the automotive industry are extremely tight, and laser cutting is a good way to meet these. Laser-cutting’s flexibility and capability to create complex shapes and designs make it a popular technology to produce car parts. In the past, car parts were created with stamping and die-cutting methods. However, these methods are not as accurate nor can they create complex shapes and designs like laser cutting. The type of laser cutter that is used in the automotive industry is a sheet metal laser cutter. Materials that are laser cut in the automotive industry include, but are not limited to, car parts, components, die-castings, forgings, and stampings.

The medical device industry utilizes laser cutting to produce a variety of products including pacemakers, stents, and catheters. The laser beam melts, vaporizes, or burns away the material, leaving a clean, precise cut. Laser cutting is often used to create products with intricate designs, such as those intended for use within the human body. The type of laser cutting used will depend on the material being cut and the desired final product. For example, some medical devices are made from stainless steel, which can be cut with a CO2 laser. Other materials, such as plastics, can be cut with a fiber laser.

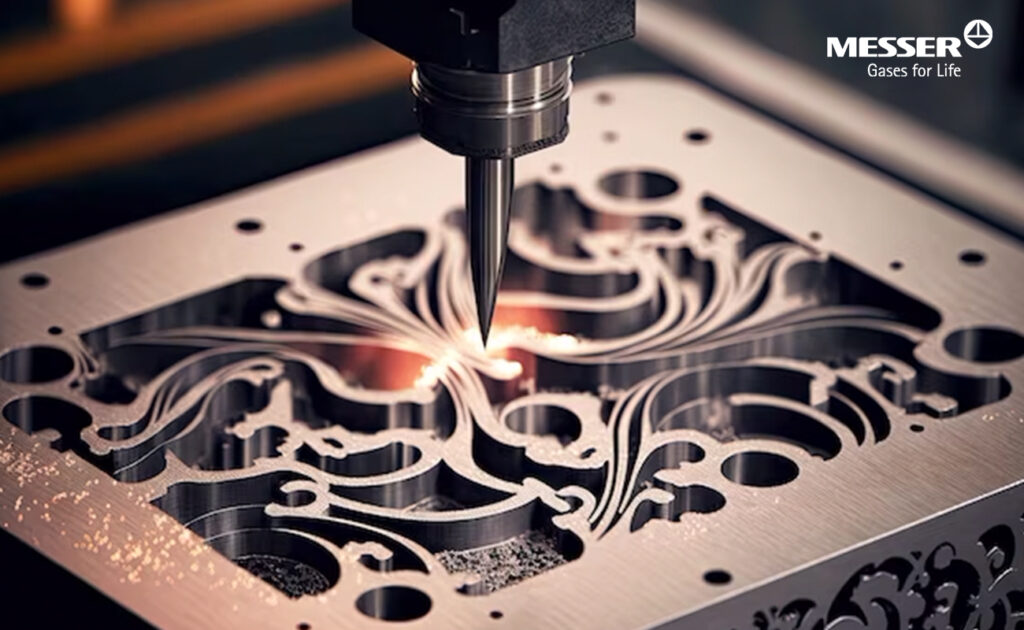

The jewelry industry is one of the most ancient industries in the world, with a long and rich history. In recent years, however, it has undergone a major transformation, thanks to the advent of laser-cutting technology. While traditional methods of jewelry making relied on manual labor and simple tools, laser cutting has allowed for a much more precise and intricate level of design. As a result, jewelry made with laser cutting is often more intricate than its traditional counterpart. Laser cutting in the jewelry industry is typically used to create detailed patterns and designs in metal, as well as to cut gemstones. It can also be used to engrave text or images onto jewelry pieces. Jewelry products that are commonly made with laser cutting include rings, pendants, earrings, and bracelets. The use of laser cutting in the jewelry industry has revolutionized the way that jewelry is made, and has allowed for a whole new level of creativity and design.

Ceramic manufacturing is the process of shaping and firing ceramic materials to create products. Ceramics can be made from clay, glass, metal, or synthetic materials. Laser cutting can be used in the ceramic manufacturing process to create precise shapes and designs in the material. This type of cutting is often used to create intricate patterns and decorative elements in products. Common examples of products made with laser cutting include tiles, pottery, and sculptures. The type of laser cutting employed in the ceramic industry is typically CO2 laser cutting, which uses a high-powered laser to cut through the material. This type of laser cutting is precise and can create very complex designs. CO2 laser cutting is also relatively fast, making it ideal for use in the ceramic manufacturing process.

When it comes to the silicon industry, laser cutting is a vital process. Silicon manufacturing refers to the production of silicon wafers—thin discs of semiconductor material that are used in the fabrication of various electronic devices. The type of laser cutting used in this industry is known as CO2 laser cutting. It is used to create the small-scale features found on silicon wafers. There are a variety of different products that are produced in the silicon industry, including integrated circuits, solar cells, and semiconductor chips. CO2 laser cutting is used to create intricate patterns on these products, which are then used in a variety of electronic devices.

Packaging refers to the process of enclosing products or items for protection and handling. Laser cutting is utilized in the packaging industry to create various packaging products, such as boxes, containers, and lids. The two main types of laser-cutting technology are used in this industry: fiber lasers and CO2 lasers. CO2 lasers are typically utilized to cut cardboard, paper, and thin plastics. Fiber lasers, on the other hand, are newer, more expensive, and typically used to cut thicker and harder packaging materials.

Metalworking is the process of shaping and forming metal into desired shapes using various tools. Laser cutting is often employed in the metalworking industry to cut metal into desired shapes. Some common products that are produced are: beams, columns, pipes, tubing, and sheet metal. These products can be used in a variety of industries, such as construction, automotive, and aerospace.

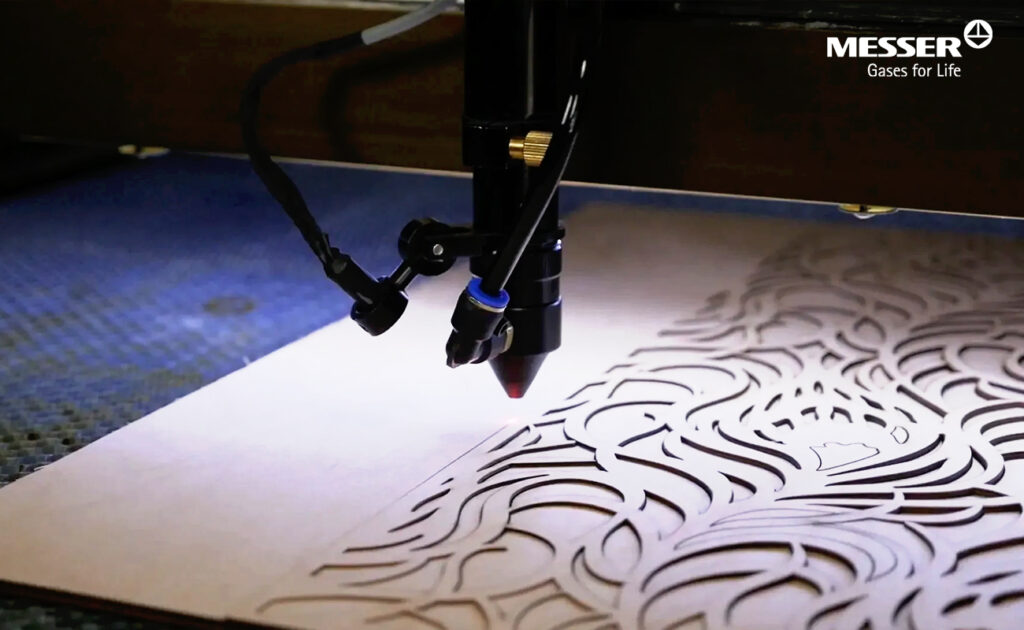

The woodworking industry is a sector of the manufacturing industry that produces wood products. These products can be used for construction, furniture making, or other purposes. Laser-cutting technology is often utilized in this industry to create precise and intricate designs in wood. Some commonly produced items are: furniture, cabinets, and decorative items. The type of laser cutting used in the woodworking industry is typically a CO2 laser. This type of laser uses a beam of infrared light to cut through wood. The CO2 laser can create very complicated designs due to the high level of precision that it offers.

The importance of laser cutting is in its highly accurate and consistent method of cutting sheet metal. It is also the most effective alternative to the etching process. Laser cutting has several advantages over other methods of sheet metal cutting, including:

For these reasons, laser cutting is now the preferred method of sheet metal cutting for many applications.

Necessary gas is used at several points in the cutting process. Depending on the system, gas performs the following functions:

Gases used as operating gases to generate the laser beam (CO2 laser)

Cutting gas

Purge gas

All laser cutting processes essentially fall essentially into one of three categories: laser oxygen cutting, fusion cutting and sublimation cutting.

The right process to use for any given application

depends on the material, the quality requirements and business considerations along with the cutting gas used.

To better understand the types of gases used in laser cutting, we invite you to read our brochure about types of cutting gases. here.

With a team of experts with many years of experience, Messer can bring you the Technical Center - an innovative source for developing new technologies in the field of welding and cutting; Gas product portfolio – comprehensive and clear; On-site in-depth consultation – right where you need it; Cost analysis – quickly and effectively; Training courses – always updated; Consulting, gas supply, technical services.

Hệ thống H2H của Messer giành được “Giải thưởng The Asset Triple A Award” năm 2024 May 17, 2024

Hệ thống H2H của Messer giành được “Giải thưởng The Asset Triple A Award” năm 2024 May 17, 2024

Messer Vietnam deploys Host-to-Host payment solution May 15, 2024

Messer Vietnam deploys Host-to-Host payment solution May 15, 2024

Mixtures for high-pressure laser cutting May 6, 2024

Mixtures for high-pressure laser cutting May 6, 2024

Laser cutting and Industries May 6, 2024

Laser cutting and Industries May 6, 2024

Understanding CCUS: How it works & why it matters May 4, 2024

Understanding CCUS: How it works & why it matters May 4, 2024

Do you have questions regarding Messer products, services and technology applications?

We are always ready to support