Welding is a critical part of the manufacturing industry. So critical, in fact, that up to 70% of all manufactured products in the US are made by professional welders.

Given the importance of the job, welding tools and supplies are in high demand. In 2023, we’re seeing some notable trends and developments that are making the welding industry safer and more competitive.

With the rise and evolution of several new technologies in the last few years, the welding process is anticipated to experience a massive shift in three particular aspects:

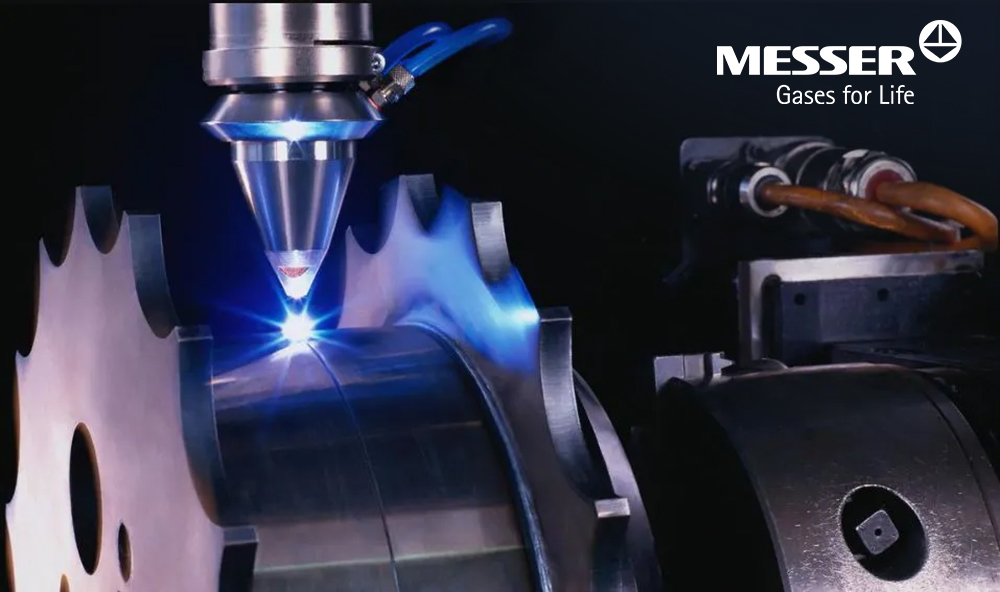

One of the newest advancements in welding involves the use of laser technology to instantly melt metal and fuse two pieces together. The laser beam is extremely accurate and enables fine welding even when dealing with extremely intricate parts.

Laser welding is said to be up to 10 times faster than conventional MIG welding. At the same time, it does not require high temperatures or multiple iterations. This makes the method effective for high-precision manufacturing processes, such as those required by the medical and automotive industries.

Industries are realizing that robots are a highly cost-effective solution, especially in mass production as they are capable of operating efficiently without errors.

Hàn robot phù hợp nhất cho các mối hàn ngắn với các nhiệm vụ có thể lặp lại và có thể dự đoán được để chúng không phải lập trình lại liên tục.

Using AR simulation is also a cost-effective way to train new welders.

Health and Safety: Newer PPE

Companies have been investing in respirators that can help protect workers from toxic fumes while also introducing PPE equipment that is better able to withstand heat, toxic fumes and ultrafine particles.

Messer, one of the largest gas companies in Vietnam has all the solutions that can help manufacturing industries and professionals become more complete with perfect welds.

With innovative research and continuous development along with a team of experienced experts, we expect to become a reputable and trustworthy companion of our customers..

Messer ra mắt chương trình mới của ZeCarb: “Thu hồi carbon dưới dạng dịch vụ” April 26, 2024

Messer ra mắt chương trình mới của ZeCarb: “Thu hồi carbon dưới dạng dịch vụ” April 26, 2024

Hiệp hội Khí Công nghiệp châu Á tại Việt Nam nhận Bằng khen của Bộ trưởng Bộ Công Thương March 29, 2024

Hiệp hội Khí Công nghiệp châu Á tại Việt Nam nhận Bằng khen của Bộ trưởng Bộ Công Thương March 29, 2024

Công nghệ Oxyfuel – thế mạnh mới với hydro March 22, 2024

Công nghệ Oxyfuel – thế mạnh mới với hydro March 22, 2024

Gases for Life March 14, 2024

Gases for Life March 14, 2024

Messer Dung Quất chào đón đoàn đại biểu Hiệp hội doanh nghiệp Đức đến thăm và làm việc March 14, 2024

Messer Dung Quất chào đón đoàn đại biểu Hiệp hội doanh nghiệp Đức đến thăm và làm việc March 14, 2024

Do you have questions regarding Messer products, services and technology applications?

We are always ready to support